Is it save to serve chicken cooked at 63ºC?

When first discovering the Sous-Vide cooking technique, is relatively common to question yourself wether it is safe to cook chicken at 63ºC. In this article we want to analyze in detail the cooking process at low temperatures, not only form the classic Time/Temperature table stand point, but we want to understand where these tables came from.

What is the Sous-Vide cooking technique?

First of all, we have the culinary technique that consist on cooking at low temperatures and on the other hand we have the Sous-Vide technique, which consists in isolating a product in a waterproof sealed container from which the air has been extracted. This air extraction can be done for various reasons such as, product conservation, to cook the product, to infusionate or marinate. What we commonly know as Sous-Vide cooking is the combination of Sous-Vide and the low temperature cooking process. This differentiation may sound confusing at first, but it is crucial to understand what we will be trying to cover in this article, how to ensure food safety while Sous-vide cooking. And to make the long story short, we will refer to it as Sous-vide.

Sous-Vide cooking is a combination of two paramettres: time and temperature. The fact that the cooking is done in waterproof and hermetically sealed bags enables to preserve all aromas and flavours. Moreover, because the cooking is done at low temperatures all nutrients will be preserved at the same time as we obtain textures that would be impossible with the traditional cooking method. But, how can we ensure a safe preparation?

How can I get a safe output when cooking at low temperatures?

According to the OMS, the salmonella(no tifoidea) is in the top 4 cause for illnesses related to diarrhea in the world. Even in the UE, where the effect is much lower compared to other regions, 92.649 cases where reported in 2017. Salmonella is a bacterial pathogen that can be found in the majority of meat or poultry. This makes it crucial to apply lethality treatments to those products before serving. Lethality is the process or combination of processes that ensures a specific, significant reduction on the number of Salmonella and other pathogens in the product.

We are talking about a significant and specific reduction raher than of a complete elimination of the pathogenic agents, which would be called sterilization. The objective is that in case the product has been polluted with pathogenic agents, these are eliminated enough so that the consumption of the product is safe. This process will also imply that the shelf life of the product will depend of the process carried out after as the conditions in which is stored.

When Sous-vide cooking this lethality process consists on applying heat and is the one we are focusing on in this post. However, we have to mention that there other lethlty treatments such as: drying, fermentation, salt curting high pressures…

The reason why the lethality objectives are centered in Salmonella is because it is the more resistent in the cooking processes among the comon ones. It has also been found that acommon cause for Salmonella outbreaks is the insufficient cooking of the product. On the contrary, in the post-lethality and stabilization treatments it is more common to focus on listeria (post-lethality) and toxins derivated from sporeforming bacterias like Clostridium perfringens and botulinum (Stabilization).

What is the pasteurization?

The US Food Safety and Inspection Service (FSIS) defines the pasteurization as any process, treatment, or combination thereof, that eliminates or reduces the number of pathogenic microorganisms to achieve at least a 5-log reduction at the end product. Keep calm, and let´s understand what this means. With everything that we have said until now it has become clear that the pasteurization is a lethality process with the objetive of reducing pathogenic agents in a significant and specific way, up to 5-log. You may have the logarithmic scales a little bit forgotten, don´t worry, we are here to explain this. The logarithmic scales are a way of displaying numerical data over a very wide range of values in a compact way. In logarithms with moving a unit of distance along the scale means the number has been multiplied by 10. Understood, so a 2-log reduction implys dividing per 10 twice, which is the equivalent of a 99% reduction (100 -(100/10)/10= 99% ), then 5-log es is a 99.999% reduction.

How to apply the pasteurization when cooking at low temperatures?

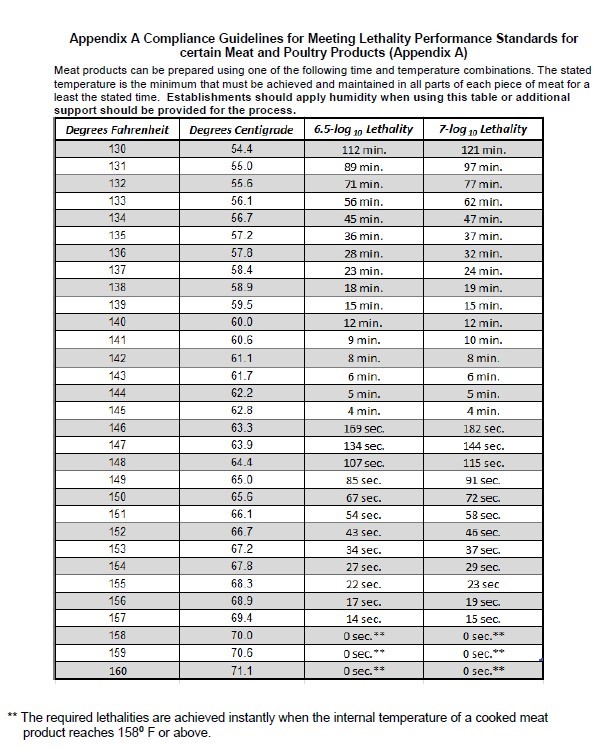

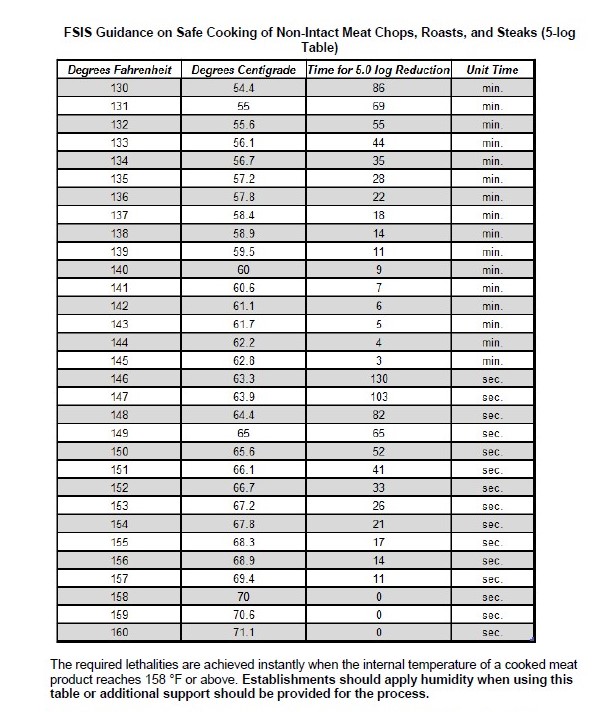

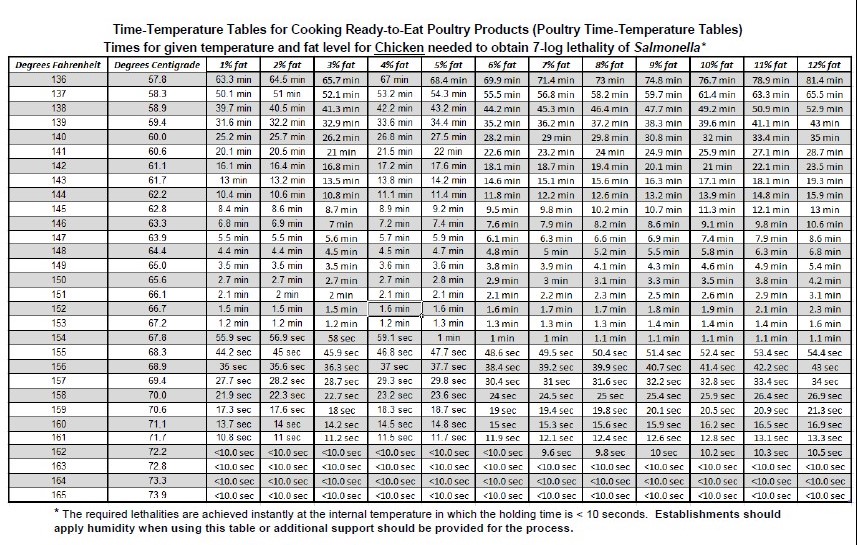

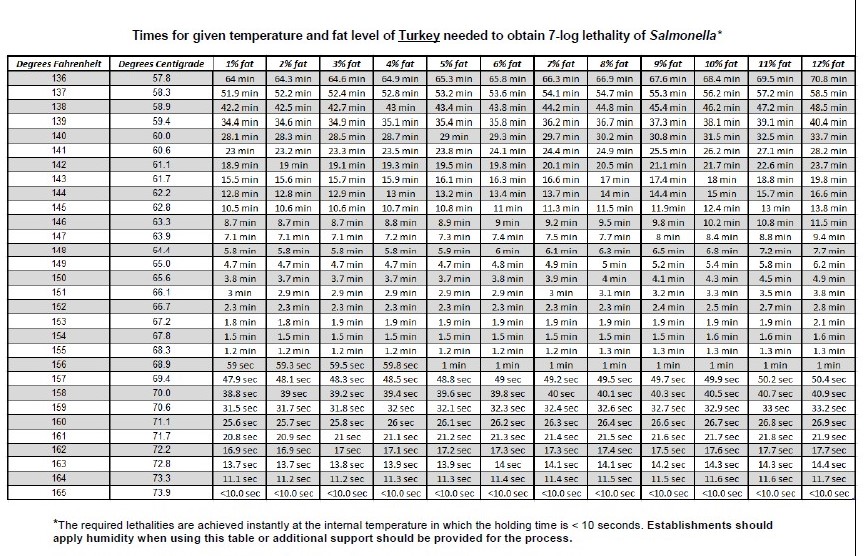

So, the definition was very precise but, how we apply this into the everyday operations in the kitchen? Luckyly for us, after several laboraory studies, we have some tables that show different time and temperature combinations that can be used for different products. The above has served to understand where the tables come from, and to understand that any of the time and temperature combinations shown in the tables represents the significant reduction of the pahogenic agents so that the consumption of the product becomes safe. However, we must not mix up these tables with Sous-vide recipes. The time and temperature combination of the tables is intended merely to the reduction of those apathogenic agents, however, the Sous-Vide recipes attend to the texture a given combination of time and temperature is able to provide in order this to be tastiest. So, the right recipe will be the one that can meet both criterias, later on we will show you some tools in order to achieve this.

If you were wondering why each protein has several time and temperature combinations, the answer is very interesting. There is a range of temperatures where pathogenic bacteria can reproduce and proliferate. Even if each microorganism has its own values, temperatures between 5 and 54ºC are considered risky. Above 54ºC microorganisms start to diminish rather than reproduce. However, this doesn´t happen immediately, it is required to maintain the temperature for as long as the tables indicate to reach the pasteurization point. For instance, with chicken, once we reach 73ºC pasteurization happens instantly. Also, if you have a look at the tables, poultry with unknown fat values, have to be kept 13 minutes at 63ºC.

What are the requirements to pasteurize?

So, if those tables existed, why have we always known 73ºC as the safe temperature for cooking? We must say that these tables are recommendations to achieve the sufficient lethalty in order for a product to be safe. But, together with them, there are some additional requirements we should apply in our low temperature cooking process.

Lets have a look:

- The temperature must be measured at the coldest point of the food we are cooking, which is refered to the internal temperature of the product, not the one of the water.

- The thermometer must be calibrated and have a 1ºF precision.

- There must be time registers during the whole process. (With a maximum of 1 minute between measurements)

- The relative humidity during the cooking process must be controlled. For instance, if we put a piece of meat in the oven into a relatively low temperature, the evaporation process will make the temperature at the surface to descend, and could make it a place for bacteria to resist. Fortunately, when Sous-Vide cooking, as the cooking is done inside hermetically sealed plastic bags, evaporation doesnt happen, so we don´t need to measure humidity.

When Sous-Vide cooking, as this is done via immersion, a foam is used between the plastic and the probe to avoid the air and water to get in contact with the food.

All the above was simplified into the before shown tables, as the values on these tables provide immediate pasteurization, which may spread the idea that all the rest were dangerous.

Which Sous-vide equipment is focused in HCCP?

Nowadays, and thanks to the Sous-Vide equipment of manufacturers like Sammic, we are able to measure the temperature at the heart of the product and to generate several records to certify that the elaboration of a given product has been safely carried out. But not only this, at Janby we wanted to contribute to the digitalization of the Sous-vide process so we have developed a registered software that automatically not only checks the process in real time, but emits notifications when pasteurization is achieved. In this way, we could set the Time and Temperature parameters that meet our texture criteria and the Janby Track will concurrently check the pasteurization tables for the given product. If the Track identifies that the product is not pasteurized this will keep it in the water until is met. Also, if for any reason the water temperature descends half way the cycle, Janby Track will reset the pasteurization times to ensure and optimize the process.

How to ensure food safety with the JANBY Track?

Janby Digital Kitchen is born to digitalize the processes in the kitchen and with its first product, the Janby Track, it digitalizes the Sous-vide process. The Janby Track, has some Active Controls that among other things take care of the pasteurization. As its name indicates, these controls work actively throughout the elaboration of a product and ensure that additional parameters to Time and Temperature are met. There are 4 of them that are focused in the pasteurization and each organization can choose which one to use according to their HACCP requirements, which may vary from industry and from country.

1. Product pasteurization control: The probe pasteurization control monitors the temperature at the heart of the product throughout the whole process and ensures the compliance of the selected sanitary regulation. Once the recipe time is concluded, this control analyzes if the accumulated time and temperature meet the regulation. If the regulation is met, the Track will put the product ready to extract, if not, the Track will maintain it cooking until this is met.

2.Continious probe monitorization: The probe control monitors the temperature at the heart of the product continiously and acts accordingly. To set this continious probe control you need to establish a minimum probe temperature to be monitored throughout the whole elaboration process. If for any reason, the temperature at the heart of the product goes below the established temperature, the recipe will be restarted.

3. Final probe measurement: the final probe measurement control makes sure that the temperature at the hear of the product once the elaboration is completed is the one the user has set. In order to do so, the operator must introduce the probe at the end of each elaboraion.

4. Continious water monitorization: The water control monitors the water tempeature continiously and acts accordingly. To set this continious water control you need to establish a minimum water temperature to be monitored throughout the whole elaboration process. If for any reason, the temperature of the water goes below the established temperature, the recipe will be restarted.

Find below the link to the official report carried out by the FSIS about the food safety measures to follow for Salmonella. The document is specifically targetd to the RTE (Ready to Eat) industry. So, some parts may not necessarily be aplicable to the restaurant industry. However, the pasteurization tables and explanations regarding lethality are valid in any context.

Disclaimer: JANBY Digital Kitchen SL cannot and does not substitute for legal or health advice about food regulations in any legal jurisdiction, nor can we guarantee that following the information presented by JANBY Digital Kitchen SL will prevent foodborne illness. Unfortunately, the many variables associated with food contamination make eliminating all risk and preventing all infections virtually impossible. We cannot accept responsibility for either health or legal problems that may result from following the advice presented by JANBY Digital Kitchen. If you operate a commercial establishment and serve food to the public, consult the rules and health regulations in your area.